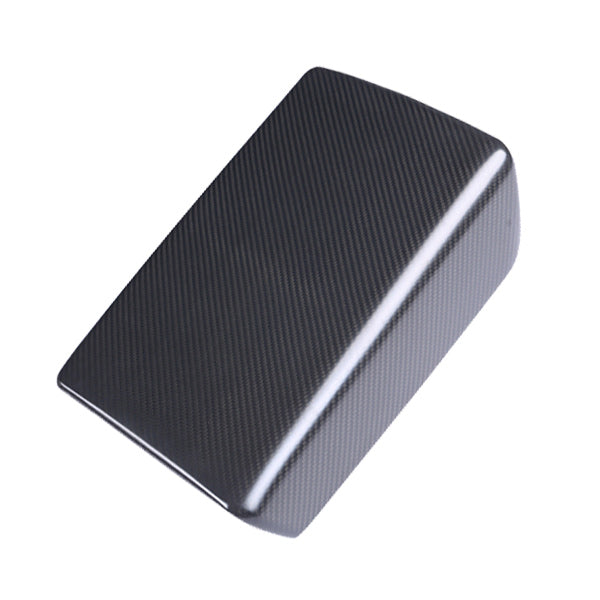

Carbon armrest

Tesla Model 3 - Y

The nobility of carbon reflections, perfect for Tesla owners who want to give their Model 3 or Y a sportier edge.

Carbon in the center of your cabin

This armrest insert will be placed on the original one by including it on the external parts.

The size of the armrest on the Model 3 and Y allows you to highlight the unmistakable presence of carbon fiber, its reflections and its aspect often associated with motorsport.

Characteristics of the carbon armrest for Tesla Model 3 and Y

- Original design: changes the look of your Tesla

- Perfect finish: in real carbon

- Applies easily: the shape wraps around your armrest

- Without glue

- Year of correspondence: Model 3 and Y version 2017-2020 and 2021-2023

-

2-year warranty

_________

Want to know what makes Model Sport carbon unique? What is a composite material? Really, what is a carbon part?

Here we will see these fundamentals in three parts:

• the true meaning of what is called a carbon element

• The unique qualities of the carbon used at Model Sport

• The most most popular in the field

The product will have no more secrets for you as soon as you have read this paragraph.

What does a composite material consist of:

A composite material is an alliance of two components that cannot bond together harmoniously, but together they give a material with improved mechanical properties.

What are the types of carbon or Texalium for your Tesla?

What we can say is that many carbon or Texalium parts exist and that many ways of presenting it in your vehicle are possible.

A distinction must be made which will be important for purists: what is commercially nicknamed "carbon" actually has the name "carbon fiber composite", this designation is much more correct in the world of stratification.

3K twill in 200gr, the use of carbon fabric:

The 3K carbon in twill weave is undoubtedly the most accustomed in its category, let's start with this one. Twill is a name that designates the structure of the intermesh of the carbon wefts.

To give you an idea, the figure just above illustrates how each carbon weft and weave, with each other. One of the arguments for the intense use of twill is undoubtedly its manageability: it is able to take the shape of almost any architecture.

There are even more in-depth details such as the 3/1, 2/2 and 4/4 interlacing, but this is not a technical development, but more of a brief explanation.

The sign annotated "3K" characterizes the total number of strands that make up a single carbon frame, in total unit: 3000 filaments. 1/20th the thickness of a hair: this is an order of magnitude that will let you know the diameter of a single strand of carbon.

To designate and mention the most widespread types of carbon and used in the different fields of industry, we must mention 1K, 3K, 6K and 12K. The 3K is the most used in the Tesla world. The term “200 gr/m²” evokes that 1 m² of carbon sheet, before treatments, weighs 200 grams. For the Tesla community, the 3K twill in 200gr/m² is the most noticed for its aesthetic aspect considered much better than its comrades, but not for its mechanical resistance provisions.

Let's talk about forged carbon:

We may think that this name of "forged carbon" is commercial or overused, however, its manufacturing process requires equipment and implementation techniques that are already a few years old and above all, which actually make it more efficient.

To make it, you first have to cut the carbon into small strips and sprinkle it more or less evenly into the mould. It is now necessary to put the resin and tighten the positive and negative master of the mold until putting them under pressure.

The mold temperature is also increased during this phase. The method used for the production of forged carbon thus gives a big advantage on rigidity and lightness, because the density of carbon obtained per square centimeter compared to the resin is higher.

Lamborghini is the pioneer in the application of forged carbon in the automotive field. However, it should be noted that forged carbon has been used in the manufacture of warheads since the 1980s.

A material worth explaining: Texalium

Texalium is an entirely different material, generally mistaken for carbon by amateurs.

It is in order to acquire the desired appearance that this material is actually fiberglass loaded with aluminum, the resin or the varnish will then be dyed to give it a specific color.

Aesthetics is essentially favored at the expense of its efficiency, because it is below the glass fabric in terms of mechanical performance. Know that Texalium is a material that has existed for years, but is little used in France. It is also much more widespread and on the Atlantic side.

What does carbon look like visually?

For this part, we will briefly give you examples of what is possible to produce with carbon fiber.

We make quotes on request if you ever have a specific project in mind.

What is the endurance of carbon?

Constantly questioned, this is a request that deserves a little more in-depth development. In reality, it is more accurate to wonder about the possible comparisons with other materials.

At equal volume, a carbon part will be more durable and much lighter than an aluminum alloy, for example. It is important to come back to the term “resistant”, because it means everything and nothing.

Even if carbon is less resistant to impacts, it has surprising qualities when twisting or bending. Carbon inserts are possible for the simple and unique reason of their tolerance to torsion and bending.

Take the example of the dashboard cover insert, which is ultra-thin. However, it should be noted that this element of more than 1.40 m can be produced using only 2 layers of carbon. We can then route throughout the French country or others who are border.

Carbon fabric and its purchase price?

What is essential to explain in order to assimilate the price of carbon, it is necessary to return to the process of production of it. The operation of manufacturing a single carbon fiber is already complex enough.

The technique that prevours over the others is composed in this way: a specific synthetic fiber, a polyacrylonitrile, will be oxidized and then calcined to finally deliver what is called carbon fiber. It takes a lot of energy to achieve such a chemical mutation.

The awareness of more and more carbon fiber production industries gives rise to certain projects, essentially directed with the aim of developing it using as few chemicals as possible. The use of bio-sourced materials is gradually emerging to eliminate chemicals on the one hand and halve the price on the other. The essential material for weaving the carbon fibers is also more than substantial, in terms of investment and space.

Keep in mind that compared to a human hair, carbon fiber is 20 times thinner. To give you a price, which remains indicative, because it is subject to variations in the world economic price: €30 per square meter. This price is given for a 3K twill carbon tablecloth that weighs 200gr per square meter.

Don't forget that we must add to this the cost of the resin, which we will see can have essentially variable prices depending on its quality, and also that very often, if not all the time, a part in carbon is produced in several sheets. Finally, an experienced laminator must be used to install the product. Moreover, the operation must be carried out under specific conditions.

The typical qualities of carbon from Model

We follow and prioritize all the production steps of our carbon components, so let's get to the most important part.

You have to turn to François SPITALS, the creator of the Model Sport brand, to find the experience necessary for the development of carbon parts.

A carbon weave or a laminated version?

It goes without saying that the carbon fabric is expressly used for its aesthetic appearance rather than its mechanical abilities.

In the Tesla domain, most carbon parts will not be subjected to any torsion or bending stress. The components are expressly manufactured in order to improve the aesthetics and highlight the aggressiveness of the brand.

Any type of carbon, even one that will be categorized as low-end, will be able to withstand the constraints imposed on it. However, there are multiple categories that will define the rigidity of carbon, the most common being HR (high resistance) because it is the most flexible and versatile.

The latter is the one employed by the Model Sport company for the production of all its carbon elements. There is also HM carbon, which is literally referred to as “High Modulus”. It is intended for productions that require extreme lightness, without any force being involved.

And if a constraint must be applied to it, it will be systematically combined with the HR. Forged carbon indicates this application primarily for appearance than for its properties, however, it does have multiple characteristics.

Which resin for carbon fiber?

Now, let's show the centerpiece of carbon elements: resin. For carbon parts that are subjected to high heat, polyester resin (the most common and the cheapest of all) will be prioritized, as for the production of carbon parts in large series.

To give you an illustration, polyester is used to make carbon cartridges for motorcycles. When it comes to building carbon parts under potential loads, Epoxy resin will give the whole composite material greater endurance.

The anti-UV resin is still a step above: no yellowing in the long term. It is for this reason that we use this type of product. The aggressions of UV rays emitted by the sun will thus have no effect on your carbon parts, what is more, the appearance is more transparent.

This is a specificity that will only be felt several years after installation, but if the anti-UV treatment is not present, beware of yellowing of the parts. You will not notice anything abnormal during the purchase for sure, it is after a multitude of summers that you will begin to observe an opaque and dull appearance of your carbon.

Several parameters come into play when buying a resin, and this is what will partly determine its initial price: its ease of application, its long-term hold and its quality of elaboration.

Let's talk about the selling price of this essential resin in France:

• 1kg of Polyester resin = 8 to 10€

• The kilo of Epoxy resin is worth between 50 and 60€

• The kilo anti-UV Epoxy resin is worth between 55 to 65€

What is the topcoat on a carbon part?

The finishing varnish is the last touch necessary for the production of carbon parts. In the past, no paint was applied to the carbon components at all. The reason is that this ensured the longevity of the elements. On the other hand, it was necessary to achieve the realization from the first shot.

This construction process gives an unacceptable scrap rate given the image that the Tesla brand wants to convey: reducing pollution and carbon waste. To remedy this, we always use high quality varnishes in order to "standardize" the finish of the carbon fiber elements.

Matte varnish gives a more luxurious finish, however, it requires extreme skill in application to achieve the desired result. The glossy finish will be polished with a polisher to guarantee a mirror effect on the surface of the parts.

Model S and X: their carbon preparation

At first glance, both vehicles have all of their interior components similar. However, a certain number of parts remain very singular depending on the year of registration.

In most cases, we therefore call the owner, after ordering, to find out more information about the vehicle.

Tesla Model S or X, personalizing its interior

Real carbon customization is also possible for the Models S and X even if they are less numerous than the Model 3.

Replacement carbon components or even inserts that will simply cover the main trim components. The predominant point, the steering wheel, can also benefit from customization with leather or Alcantara trim, depending on your choice.

The latter will have a relatively precise focus, which many other accessories will be able to benefit from in the future.

Let's move on to the Model S and X bodywork

The electric sedan par excellence first receives the Performance spoiler. Always keen to make a difference, the matt Performance spoiler will benefit the Model Sport version from a rectified bonding surface and a lighter internal structure.

This change is subtle, so much so that it will not be visible once the spoiler is put down, however these details make all the difference. The Plaid version is also in production at the time of writing this paragraph. The carbon finish is so versatile and in demand as components such as the mirrors or even the grille.

Generally in a glossy or matte finish, carbon will be in most cases 3K twill, however if you want a creation based on Texalium or forged carbon, send us a request directly by phone or email , so we can provide you with a personalized quote for your Model S or X.

The Model 3 and Y: perfect bases for carbon projects

The most modified electric vehicle of all time is undoubtedly the Tesla Model 3, which receives an incredible number of carbon-based evolutions.

Share a lot of similarities with the Model Y, let's see what else you can find on them.

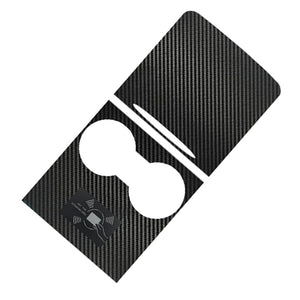

Model 3 and Y interior

Part of the Tesla family of owners became aware of the carbon inserts for Model 3 or Y. It is an exercise in strength to be able to mass-produce carbon elements that can cover a part while giving the impression that there is no addition. The inserts find here all their interest and their quality of production.

It is for this argument that it took us many attempts to finally succeed in manufacturing extremely thin inserts to cover a dashboard, a door trim, a central console or even an armrest. while giving the impression of being part of the original finish.

The key to a quality insert is precise cutting and precision gluing. Replacement elements such as the carbon dashboard combined with door trim will give your vehicle a real finish in the chosen material.

For the most demanding of you who like beautiful parts with meticulous manual work, the carbon dashboard and door trim will satisfy you.

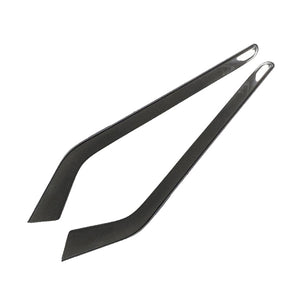

Model 3 and Y bodywork

The Model Y or 3 bodywork is not to be outdone with a good number of possible carbon-based customizations. Here too, in a 3K twill or forged version, you will have the choice between the matte or shiny finish.

The Performance spoiler is a must in the series of carbon parts for Model 3. The same goes for the Model Y. Having become almost a standard in the Tesla world, it will be fixed directly on the edge of the trunk.

In addition, you can order more essential upgrades such as the real carbon bonnet exchange. First, it will allow for weight loss, but will give the car a style that is out of the ordinary.

- 🇫🇷 Gestionnaire Français

- Commandez directement au Fabricant ou au Distributeur

- Payez que votre produit (pas de frais de stockage ni de taxe territoriale)

- Livraison dans toute l'Europe !

Vous remarquerez que le bouton au-dessus vous redirige vers un des distributeurs ou fabricants du produit.

La major partie des accessoires Tesla proviennent de Chine, commander via les plateformes Aliexpress, Alibaba, Amazon, Hansshow ou Jowua vous donnera la possibilité d'obtenir le produit sans intermédiaire.

Les produits vendus en France ou en Europe proviennent du même fabricant Chinois (ou autre), mais avec une marge supplémentaire servant à payer les frais de fonctionnement de la société.

Cependant, l'avantage de commander à proximité est d'obtenir un délai de livraison plus rapide (néanmoins nous proposons aussi des produits expédiés directement depuis des stock Français ou Européens)

Model Sport a initialement commencé en faisant du stock en France, nous connaissons donc quels sont les fabricants de confiance et leur méthode de travail. Si bien que nous les citons avec leurs accords : MAOFA, BFB carbon, Yute Technologie, DCR Tuning, LITA Accessories, Jogon, Ever carbon, Carbonss Tuning, Jowua.

Ces fabricants, parmi quelques autres, sont les plus actifs et sérieux dans leur qualité de fabrication. Nous vérifions que les produits proviennent systématiquement de notre liste de fabricant. Ainsi, que vous commandiez via un distributeur Aliexpress, Amazon ou autre, nous savons que le produit sera de bonne facture.