Carbon glove box insert

Tesla Model 3 - Y

For carbon lovers, the glove box of the Model 3 or Y is also entitled to its insert. To stick directly on its support with the double-sided.

Enjoy a large surface to display the carbon

The glove box featured in the Tesla Model 3 and Y features an extended surface area to showcase the unique depth of real carbon.

This insert will give continuity to the dashboard (see images) and will add an element more focused on the sportiness specific to the American brand.

Features of the carbon glove box insert for Tesla Model 3 and Y

- Original design: changes the look of your Tesla

- Perfect finish: in real carbon

- Applies easily: durable 3M double-sided

- Does not leave glue residue after uninstallation

- Year of correspondence: Model 3 and Y version 2017-2020 and 2021-2023

-

2 year warranty

_________

Are you interested in Model Sport's carbon production logic? What is a composite material? The usefulness of a carbon part in the different industries?

We will focus our analysis around three paragraphs:

• the true meaning of what is called a carbon element

• The advantages of carbon at Model Sport

• The most popular products in the field

You will be able to afford a carbon component with confidence.

Composite material: what does it mean?

By definition, what is called composite material is the assembly of two elements together, which does not mix, but which produces an object more resistant to shocks / impact / torsion / bending than if they are used independently l each other. Typically you can take reinforced concrete as an example.

Carbon or Texalium, what can you find for your electric?

What we can mention is that a lot of carbon or Texalium parts are present and that there are many ways to present it in your vehicle.

What the accustomed mortals call "carbon" is actually determined by "a composite of carbon fiber", you should know that in the field of lamination, it is this term that is used.

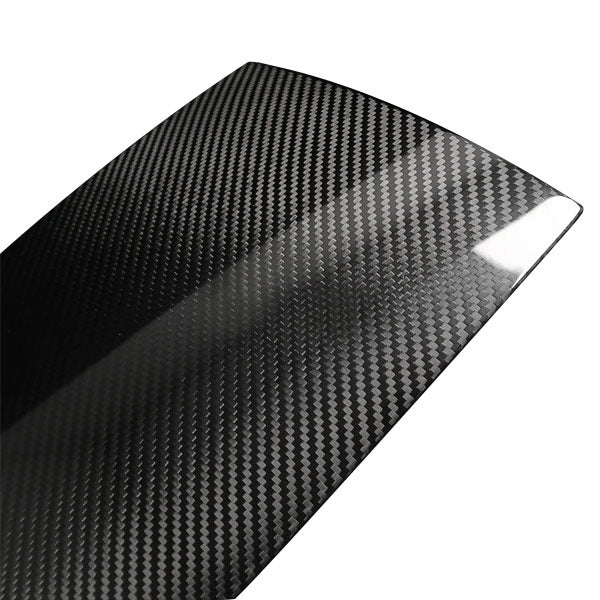

3K twill carbon fabric in 200gr/m²:

Let's start with the most familiar of carbon fiber composites, 3K carbon in twill mesh. Each way of weaving carbon has a specific name, that of twill is one.

You can see what the twill evokes in the image just above. There is a reason why the twill is very noticed: firstly its ability to adapt to the molds with a strong curve, secondly its aesthetic aspect giving the impression of a diagonal weave. However, we will not clarify the type of interlacing in 3/1, 2/2 and 4/4 for the sake of understanding.

The abbreviation "3K" evokes that 3000 carbon filaments are part of a single frame. To give you a fairly precise order of magnitude, the thickness of a strand of carbon is 1/20 of that of a hair. 1K, 3K, 6K and 12K are the most used varieties in the automotive, motorcycle, aviation or other types of carbon used in large industries.

In the Tesla world, 3K is systematically the one used. As for the weight stated when selling a carbon sheet, if it is mentioned "200gr/m²", this states the weight that 1m² of this sheet weighs before it is confused with a resin. The combination of carbon characteristics that you come across the most is the twill weave in 3K and 200gr/m², not for its mechanical provisions, but more for its aesthetics and its widespread use in many industries, which makes it cheap.

Forged carbon:

A denomination that may seem abusive for an aspect that is very divergent from the standards, however, this molding technique is nothing new.

To give you a simplistic designation, so-called "forged carbon" refers to a unique production process: the carbon fiber is cut into small pieces and then dispersed evenly in a mold.

Then, the positive and negative molds are put under specific temperature and compression conditions once the resin is added. Why use this crafting process?

Simply to condense more carbon for less resin. All the excess resin is ejected during the pressurization phase. So you get a stiffer and lighter part. Lamborghini is the pioneer in the automotive world to have used the latter. Note all the same that its appearance and application has been present since the 80s concerning the production of missile heads.

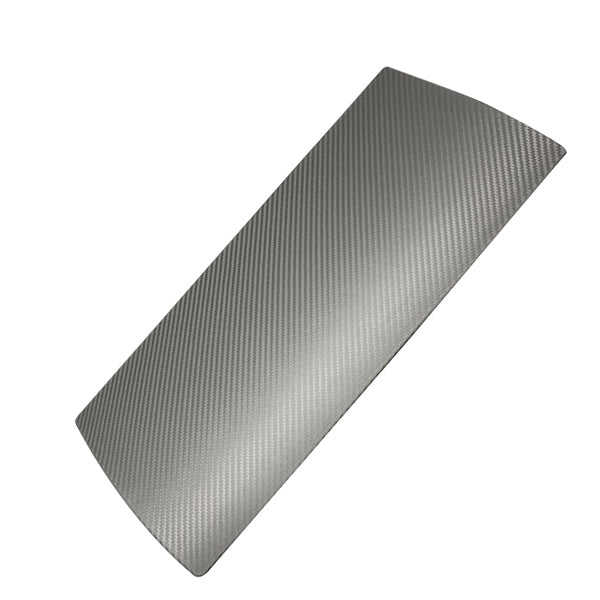

Texalium, the unusual:

Often confused with carbon, Texalium is a material in its own right that deserves its place in this definition.

Really, Texalium is a kind of glass fabric loaded with aluminum to give it a natural highlight. It can thus be dyed either in the mass, by mixing a dye with the resin, or on in the varnish.

An entirely decorative use for this finish, because its mechanical provisions are less compared to simple glass fabric (which itself is below carbon). We have to wait longer for other countries to see a novelty arrive here, Texalium is no exception to the rule, because it has been widespread in the United States for a few years, while it is only just becoming known in France.

Carbon: what does it look like?

With carbon fiber, what exactly can you make?

If you are interested in a product or part, Model Sport can provide you with a quote.

Is carbon resistant?

This question deserves an adequate answer once and for all. In truth, it is more accurate to wonder about the possible comparisons with other materials. To give you an idea, even at equal volumes, a carbon part is relatively stronger than an aluminum alloy part.

However, this term "resistant" sums up a fact that is not to be spread. Even if carbon is less resistant to impacts, it has surprising qualities when twisting or bending.

It is for this reason that for Tesla automobiles it is so common to produce ultra-thin carbon inserts that stick on existing parts without risk of breakage. The dashboard insert for the Y or 3 models is worth mentioning: this element is only useful for its aesthetics (as with most carbon elements for Tesla).

However, it should be noted that this object of more than 1.40 m can be produced using only 2 layers of carbon. It can then be shipped throughout France without suspicion of breakage.

Carbon fabric and its purchase price?

To understand its final price, you must first understand its production:

Let's see how the development of a single carbon frame takes place. To roughly characterize the stages of production of a single carbon fiber, you have to start your work with a synthetic fiber called polyacrylonitrile, this one will be put under oxidation then then logically calcined to offer us this inimitable carbon fiber. .

As you can imagine, the production of carbon fiber involves a number of chemicals that are not good for the environment. It is for this reason that many institutions are creating projects to continue the production of carbon fiber in the future, while drastically reducing the application of unnatural products.

The use of bio-sourced materials is gradually emerging to eliminate chemicals on the one hand and halve the price on the other. The tools essential to the production of the raw material of carbon are substantial, as are for its weaving.

Keep in mind that compared to a human hair, carbon fiber is 20 times thinner. For information, the square meter of the carbon fabric is acquired at the price of 30 euros. This applies in particular to the 200 g/m² twill 3K carbon.

Don't forget that we must add to this the cost of the resin, which we will see can have totally variable prices depending on its quality, and also that very often, if not all the time, a part in carbon is produced in a multitude of webs. We also need a laminator with experience in laying carbon materials.

The carbon dissimilarities of Tesla Model Sport

We follow and prioritize all the production steps of our carbon components, so let's get to the most important part. It takes knowledge of the actual shape of an element to be able to ensure an acceptable result.

It is for this reason that the creator of the Model Sport brand, designer and bodybuilder, makes every effort to deliver its know-how in the field of carbon components.

A carbon weave or a laminated version?

It goes without saying that the carbon fabric is expressly used for its aesthetic appearance rather than its mechanical faculties. To name just a few benefits of carbon: its endurance to torsion, bending and its lightness.

However, these features are often overlooked in the Tesla world.

The components are expressly manufactured to enhance the aesthetics and highlight the aggressiveness of the brand. The constraints will be largely cashed on the Model S, 3, X or Y equipped with a body kit, even if it uses low-end carbon (be aware that it is difficult to manufacture carbon known as "bad qualities ").

Moreover, the most used category, even the most standard, is the HR, for "high resistance", which is very appreciated for its versatility and its competence of flexibility. For all the carbon parts of your Tesla, Model Sport is also based on this type of carbon which is very widespread and so practical on a multitude of points. There is also HM carbon, which is literally defined as “High Modulus”.

It is intended for creations that require extreme lightness, without any constraint being involved. And if a constraint must be affixed to it, it will be systematically combined with the HR. The reference we can provide concerns forged carbon: it is commonly used for its appearance, however its primary purpose is unconventional resistance.

The important role that resin plays in assembly

This is THE biggest difference that Model Sport carbon parts can boast of making, an epoxy resin making the difference. The mass production of certain carbon components is generally produced with polyester resin.

It is inexpensive and resists high heat quite well. To give you an image, the polyester is used for the elaboration of carbon cartridge of motorcycle. When it comes to building carbon parts under potential loads, Epoxy resin will give the whole composite material greater endurance.

It is a good omen to specify that on this point, we make the difference: the application of an anti-UV epoxy resin is obvious for Model Sport, this one prevents yellowing of the parts over time. The aggressions of UV rays emitted by the sun will thus have no effect on your carbon parts, what is more, the appearance is more transparent.

This is the strongest point of this type of resin: the parts will not yellow in a few years. Not mentioning this point is a lack of knowledge: if the treatment is not present, beware of too hot summers which will give the carbon parts a duller appearance. As a result, three parameters enter into the calculation of the price of the resin: its application, its quality and its longevity.

To give you an idea, here are approximately the prices you can find on the French market:

• 8 to 10€ for the kilogram of Polyester resin

• 50 to 60€ for the kilogram of Epoxy resin

• 1kg of anti-UV Epoxy resin = 55 to 65€

Concordance of the topcoat on a carbon part

It must be said that it is the operation that closes the project. In the interests of ultimate quality, we had produced parts without topcoats at the very beginning, which required uncompromising production quality the first time around.

Tesla's nerve center is to promote pollution reduction, so the high scrap rate of this production technique was ultimately a problem.

We therefore use superior quality varnishes to "standardize" the finish of our carbon parts. The glossy varnish is finely polished before dispatch and the matte varnish applied delicately to have a uniform appearance over the entire piece.

Carbon weaving on the Tesla Model S and X

Even though there are many customary points between the two models, there are still some notable differences depending on the production date.

It is with this in mind that it is necessary for us to call you, after ordering, to find out the year and month of production of your vehicle.

Model S and X interior

Tesla component tuning is much more popular on the Model 3, however your Model S and X can also receive interior upgrades. The dashboard, the cup holder area or even the central console can receive a trim that differentiates it from the original.

Forged carbon or 3K twill can complement a sports steering wheel, but also leather or Alcantara trim will complete the development of this one.

For the latter, we offer a very precise personalization service on demand which will give you total control when placing your order.

Let's move on to the Model S and X bodywork

The performance spoiler for the Model S is the most sought after for the latter. As with all Model Sport spoilers, the internal structure as well as the entire bonding surface are ground in advance.

This change is subtle, so much so that it won't be visible once the spoiler is installed, however these details make all the difference. The Plaid version is also in production at the time of writing this paragraph.

The carbon finish is so versatile and in demand as components such as the mirrors or even the grille. Model Sport remains flexible and will respond to your request in case you want to achieve finishes other than 3K twill carbon.

Carbon manufacturing on Model 3 and Y

The Model 3 marked the advent of carbon in the Tesla world: it is the most modified electric vehicle today.

Tesla's two best-selling nuclear cars share a lot of similarities.

Model 3 and Y and their interior modifications

Carbon inserts are almost standard equipment for the Tesla community. A successful carbon insert must partly be finely cut so as not to give an "add-on" effect.

This is why it is so difficult to develop it in series. The inserts find here all their interest and their manufacturing quality. The door trim, dashboard and other center console required a number of different tests to find the right method and the right mold to manufacture these inserts of incomparable quality.

An adjusted cut and gluing as close as possible to the components with a perfect finish, this is the recipe for a successful carbon insert for Model 3 or Y. But you can just as well opt for a real carbon replacement element, which will be positioned directly in place of the changed part.

Replacement carbon elements will give a totally unique dimension to the interior of your Tesla, for meticulous people, you will get a finish that meets your expectations.

The body parts of a Model Y or 3

Again, for the Model 3 and Y, the bodywork improvements with carbon elements are really good. You can completely transform your Tesla using 3K twill or forged carbon.

It concerns matte or glossy finish. The most requested carbon part is undoubtedly the Performance spoiler in its matt version. To stick directly on the trunk (or trunk for the Model Y), it has become a standard for Tesla personalization.

To combine the two benefits of carbon, which are weight loss and a sportier appearance, you can opt for a more substantial improvement such as the carbon front cover.

- 🇫🇷 Gestionnaire Français

- Commandez directement au Fabricant ou au Distributeur

- Payez que votre produit (pas de frais de stockage ni de taxe territoriale)

- Livraison dans toute l'Europe !

Vous remarquerez que le bouton au-dessus vous redirige vers un des distributeurs ou fabricants du produit.

La major partie des accessoires Tesla proviennent de Chine, commander via les plateformes Aliexpress, Alibaba, Amazon, Hansshow ou Jowua vous donnera la possibilité d'obtenir le produit sans intermédiaire.

Les produits vendus en France ou en Europe proviennent du même fabricant Chinois (ou autre), mais avec une marge supplémentaire servant à payer les frais de fonctionnement de la société.

Cependant, l'avantage de commander à proximité est d'obtenir un délai de livraison plus rapide (néanmoins nous proposons aussi des produits expédiés directement depuis des stock Français ou Européens)

Model Sport a initialement commencé en faisant du stock en France, nous connaissons donc quels sont les fabricants de confiance et leur méthode de travail. Si bien que nous les citons avec leurs accords : MAOFA, BFB carbon, Yute Technologie, DCR Tuning, LITA Accessories, Jogon, Ever carbon, Carbonss Tuning, Jowua.

Ces fabricants, parmi quelques autres, sont les plus actifs et sérieux dans leur qualité de fabrication. Nous vérifions que les produits proviennent systématiquement de notre liste de fabricant. Ainsi, que vous commandiez via un distributeur Aliexpress, Amazon ou autre, nous savons que le produit sera de bonne facture.